320kN DUAL Shaker

General Description

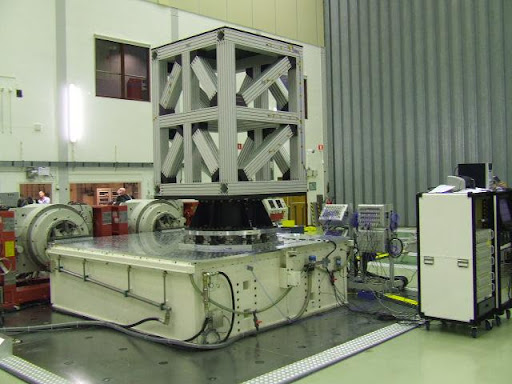

The 320kN DUAL shaker is a classic electro-dynamic vibration test facility for large S/C payloads with a mass of up to 10 tons in horizontal configuration. The facility operates in a frequency regime of 3Hz - 2000Hz. The two identical 160kN shakers are water-cooled electro-dynamic shakers based on a long-stroke vibrator V984 with a nominal thrust of 160kN continuous. The shaker facility can be configured for vertical or horizontal excitation. For horizontal, the two shakers are coupled to a so-called slip table which provides a very stiff mechanical interface that can admit large overturning and rotational moments. Excitation in vertical direction can be performed on either one of the single V984’s, providing an interface for small S/C or S/C subsystems. A full-blown structural analytical model of the facility is available for coupling with the specimen model to predict test item behaviour.

Test modes

The vibration input is generated by a state-of-the-art vibration controller with up to 48 control and measurement channels, all usable for test article response limiting.

A variety of types of excitation is available:

- Sine testing, e.g. sine sweep, tracked sine dwell

- Random testing

- Transient testing, e.g. classic half sine shock, saw-tooth, transient waveform replication/SRS

Test article responses are measured by a mechanical data handling system, offering up to 800 channels.

Mechanical Interface

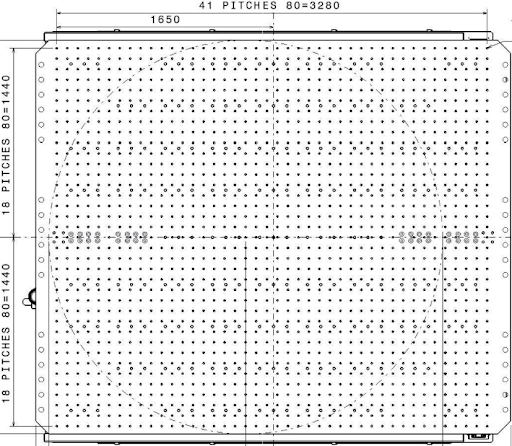

Horizontal:

The test article is mounted to the 3x3.5m light large slip table using an 80x80mm M10 hole pattern.

Vertical - single shaker:

The test article can be mounted either directly on the shaker armature interface, on various unguided adapters or on top of a guided single head expander that offers a 1.1m circular mounting surface with a 80x80mm M10 hole pattern.

TECHNICAL PARAMETERS

DESCRIPTION

HORIZONTAL CONFIGURATION

SINGLE HEAD EXPANDER CONFIGURATION

Nominal maximum thrust:

- Sine testing [kN]

320

160

- Random testing [kN RMS]

310

155

- Transient testing [kN peak]*)

930

495

Frequency range:

- Sine testing (min-max) [Hz]

3 – 2000

3 – 2000

- Random testing (min-max) [Hz]

10 – 2000

10 – 2000

- Transient testing (min-max) [Hz]

10 – 2000

10 – 2000

Maximum displacement:

- Sine and random testing [mm p-p]

20

20

- Transient testing [mm p-p]

38

38

Maximum velocity [m/s]

1.5

1.5

Maximum no-load acceleration:

- Sine testing [g]

20

20

- Random testing [g RMS]

13

30

Sine testing with 100 kg load [g]

_

27

Minimum controllable level [g]

0.1

0.1

Fundamental resonance frequencies (bare test facility) [Hz]

400

1100

Maximum static vertical load [kg]

10000

2000

Allowable overturning moment [Nm]

600000

600

Mass of the moving assembly [kg]

1609

369.5