Large European Acoustic Facility

General Description

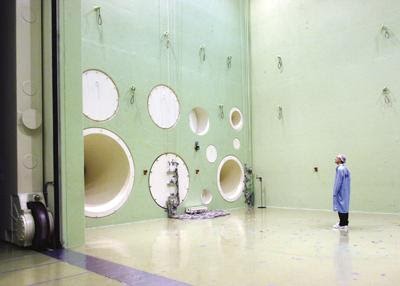

The Large European Acoustic Facility is used to perform acoustic noise tests on launcher subsystems, Spacecraft and their payloads or external appendices to assure that no damage will occur during the rocket launch.

The facility accurately replicates launcher-specific sound pressure levels warranting the characteristic spectral content existing in the launcher payload bay. The sound pressure levels inside the acoustic chamber are automatically controlled using arrays of special microphones to provide the feedback signal to the controller.

The 48-channel automatic control system easily adapts to launcher requirements and is designed to ensure short and smooth ramp-up as well as very stable spectral noise levels throughout the actual noise exposure.

The noise generation system consists of four large exponential horns with cut-off frequencies of

- 25Hz

- 35Hz

- 80Hz

- 160Hz

plus three high frequency generators:

All together allowing acoustic excitation in the frequency range from 25Hz to 10kHz and an overall noise level of up to 155dB OASPL.

To achieve such extraordinary sound pressure levels, the four unique noise generators generate an equivalent acoustic power of up to 120 kilowatt. Specimen vibro-acoustic responses can be recorded by a mobile data handling system, offering up to 800 channels.

Mechanical Interface

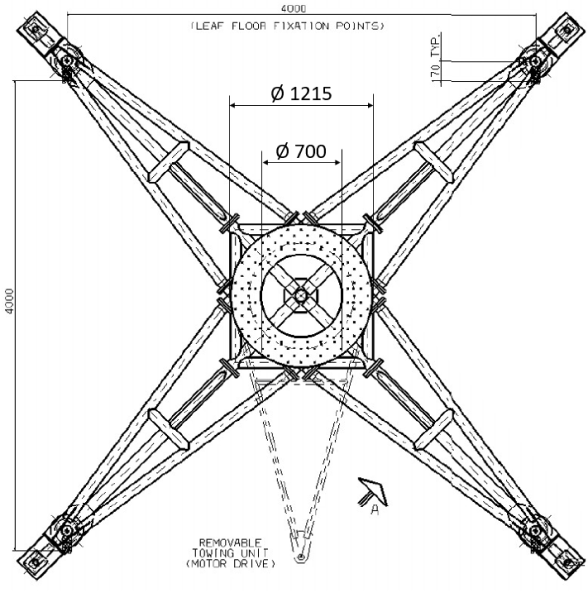

- LEAF spider:

Using an 80x80mm M10 hole pattern, the test article is mounted to the stainless steel interface ring of a wheeled steel structure that is placed in the LEAF chamber on integrated air cushions.

- LEAF ISL trolley:

A Ø 2800mm steel ring on a air cushion-suspended cross frame with adaptable mounting interface plate for dedicated hole patterns.

- Individually tailorable test stands:

Generic test stands