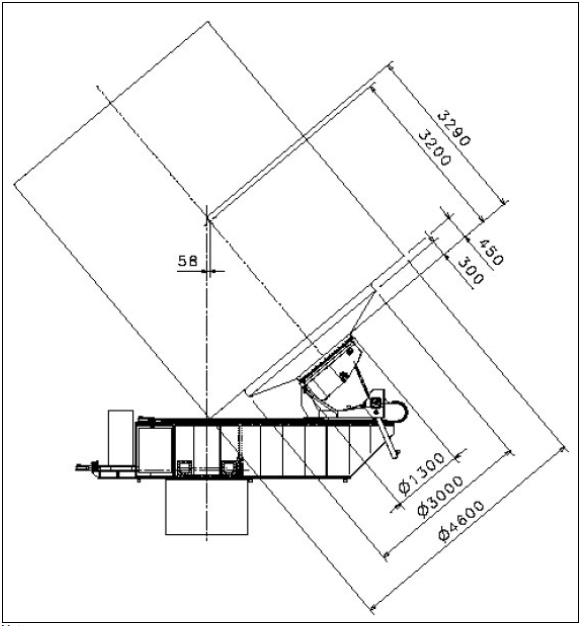

M80/MPMA Moment of Inertia Machine

General Description

The M80 moment of inertia machine is designed for Moment of Inertia (MoI) measurements at ambient pressure. In combination with the MPMA, the specimen longitudinal COG can be accurately determined.

The M80 machine consists of a table oscillating on air bearings and restrained by torsion spring.

The working principle of the M80 machine is based on the measurement of the rotational oscillation period of the test object about a vertical axis.

For small oscillation amplitudes the product of calibrated spring constant K and squared oscillation period T equals the moment of inertia.

The 3 degree of freedom mass property measurement adapter MPMA is stacked on top of the M80 machine, providing the possibility to tilt the test item, rotate it and translate it along the machine axis.

An automatic motion control software ensures safe operations, keeping the assembly centre of gravity always above the vertical M80 machine axis by means of an internal movable ballast.

By running a sequence of several oscillation measurements at incremented positions across the translation axis, the position of the minimum calculated MOI value represents the projected value for the test item longitudinal centre of gravity.

Using this method, also the products of inertia POI are determined.

Mechanical Interface

M80:

- 2 concentric hole patterns of 16 x M12 threaded holes equally spaced on 560 and 750mm PCD

- 2 concentric hole patterns of 16 x M16 threaded holes equally spaced on 900 and 1120 mm PCD, including 50mm diameter H7 centring device

MPMA:

- 2 concentric hole patterns of 14 x M12 threaded holes spaced at 22.5 degree angles on 560 and 750 mm PCD including 5mm diameter H7 centring device

- 2 concentric hole patterns of 14 x M16 threaded holes spaced at 22.5 degree angles on 900 and 1120 mm PCD including 20 mm diameter H7 centring device

M80

Description

Quantity

Maximum capacity load [kg]

17 000

Mol range [kg m2]

0 – 46 000

Maximum Allowable OTM (clamped) [kg m]

4000

Maximum Allowable static OTM (clamped) [kg m]

600

Spring factor M80 torsion spring [Nm]

(approx..) 425.7

I/F table diameter [mm]

1250

Positional Accuracy [mm]

+/- 0.3*)

Mol Measurement Accuracy [kg m2]

+/- 0.1% (min.0.23)

* Errors generated by uncertainty of positioning the tst objects are not taken into account.

MPMA

Description

Quantity

Mass (unloaded) [kg]

(approx..) 3700

Mol (empty) [kg m2]

(approx..) 4000*)

Mass loading capacity [kg]

5000

Roating head I/F [mm]

1250

Minimum flatness I/F [mm]

0.1

Relative Positional Accuracy (translation) [mm]

0.1

Relative Positional Accuracy (rotation) [deg]

0.02

*) Note: Dependent pf inclination ange (0 – 40 deg.)