Thermo – Elastic Deformation Measurement

General Description

In ambient, vacuum and cryogenic environmental conditions, thermo-elastic deformation measurements can be performed with a dedicated high speed videogrammetry measurement system.

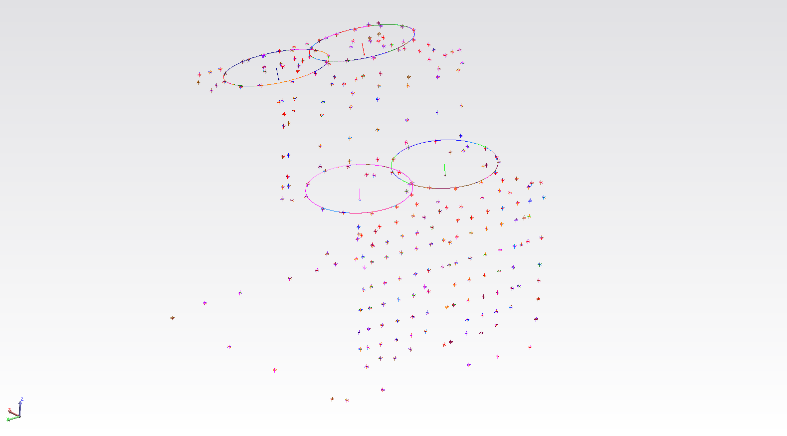

The system is built of up to 8 monochrome micro cameras that survive the extreme conditions in the test chamber.

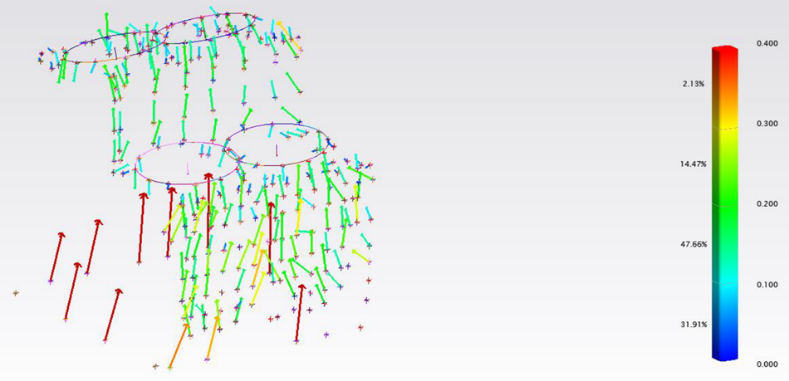

The measurement method is based on close-range photogrammetry, a technique which can retrieve 3D data from the acquired images.

With the use of reflective targets, the system can measure the 3-dimensional displacement across the thermal test at micrometer level.

Traceability is guaranteed with the use of calibrated scale bars, made of carbon fibres and Zerodur glass. Because the system is fully portable, it can be used in any facility.

The measurement set-up of the system is flexible, depending on the test volume and areas of interest on the test object. The optimal set-up can be designed and assessed with an in-house simulation tool.

Main parameters of the videogrammetry system

Cameras

8x Basler Ace acA2040-25gmNIR, 2x RGB

Resolution

2048 x 2048 and 0.0055x0.0055 mm pixel size

Field of view

60° diagonal

Power consumption

2.9 W

Mass of camera

200 gram

Accuracy

Relative 3D precision 10-30 ppm /

Absolute 3D accuracy 50 ppm

Frame rate

25 fps

Scale bars

Zerodur and CFRP

Operating Temperature

90 – 313 K

Operating Pressure

1 bar – 10E-6 mbar