Virtual Shaker

General Description

“Virtual Testing” has become in recent years more and more a common topic in the world of environmental testing. What is meant by it is to perform high fidelity multi-domain simulations with the validated model of the facility in the loop prior to the physical test.

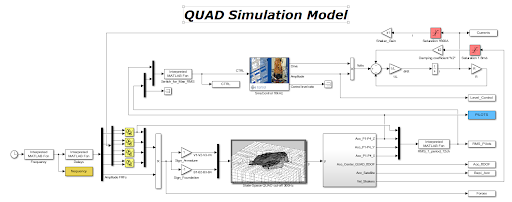

For vibration testing, the model includes the control system, the physics of the actuators, the stiffness of the table and guide system, the location and feedback of the control sensors etc. The ESTEC Test Centre has developed and validated such a platform for its three largest shakers: HYDRA, QUAD and LLST.

Customer input is a FE model of the test article at the relevant development stage. The simulation output provides critical insides such as facility performance issues and Eigen frequency shifts with respect to cantilever predictions before the test takes place.

The main advantages

- Predict test facility performance before the test campaign

- Assess frequency shift of main modes due to coupling with the facility with respect to cantilever boundary condition predictions

- Assess notching profiles behaviour before the test campaign

- Optimize control parameters such as compression factor or pilot placement before the test to achieve optimal performance

- Aid in correlating the spacecraft FEM post test

Validated simulation platforms are available for the HYDRA vibration facility, the QUAD shaker and the DUAL shaker.