Feel the Force

Going to space equals stress. As launcher propellant tanks are filled with fuel, or spacecraft structural panels experience the strain of orbital ascent, they undergo major force loading in multiple directions at once.

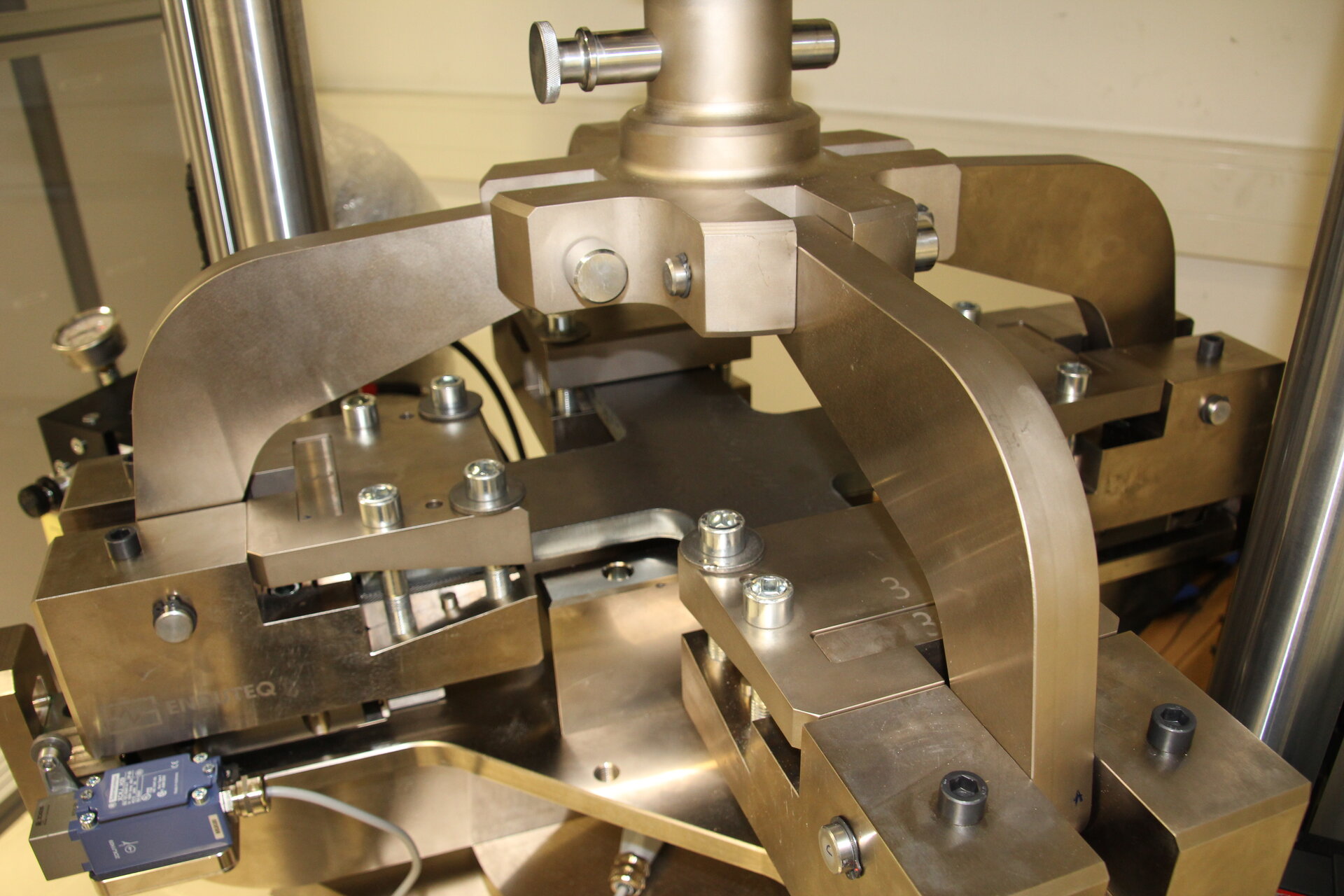

ESA’s new Bi-Axial Test Facility – installed at the Agency’s Materials and Electrical Components Laboratory at its ESTEC technical centre in the Netherlands – replicates the bi-directional application of load, allowing higher-fidelity testing of candidate materials for space missions.

“This is a new add-on to our existing Instron hydraulic test system, which is able to apply up to 250 kilonewtons of force in a single direction,” explains ESA materials engineer Donato Girolamo, who commissioned the design of the new facility to fulfill space material testing requirements.

“This is a new add-on to our existing Instron hydraulic test system, which is able to apply up to 250 kilonewtons of force in a single direction,” explains ESA materials engineer Donato Girolamo, who commissioned the design of the new facility to fulfill space material testing requirements.

“This extra jig works somewhat like a car jack. It has four rotating arms connected to sliding clamps onto the sides of the test item. Then as the hydraulic load is applied these arms rotate and the clamps slide outwards, pulling the material out along all four directions, to apply loading in both the x and y axes.”

Such bi-axial testing is especially valuable for composite structures, widely used in space, which can possess differing material properties along different directions.

Feel the Force Pillar

The custom-made tooling for the new facility was designed and built by Enduteq in the Netherlands.

The Bi-Axial Test Facility will begin by investigating the performance of solid rocket motor cases. It would also be suited to testing materials making up structural panels, as well as those for pressure chambers of all kinds, from propellant tanks to crewed modules.

“This expansion of our capabilities allows us to reproduce the real load conditions facing our test materials and structures more closely than ever,” remarks Tommaso Ghidini, heading ESA’s Structures, Mechanisms and Materials Division.

“This is one example of how we are continuously working to enhance our testing capabilities to better serve our customers, shrink uncertainty margins and improve the performance of European spacecraft and systems.”