Life Support and Physical Sciences Instrumentation Laboratory

Supports work on life and physical sciences instrumentation and experiments for microgravity research, life support and environmental control and other exploration related activities

For testing requests, access to lab facilities, training and consultancy services, please refer to:

Laboratory Overview

The Life Support & Physical Sciences Instrumentation Laboratory supports work on life and physical sciences instrumentation and experiments for microgravity research, life support and environmental control and other exploration related activities, including experimental testing or rehearsing space mission payloads, life support system development or activities for planetary exploration. The Lab can investigate and test a wide variety of factors, including prolonged effects of simulated low-, partial- or hyper-gravities. Its facilities also support flight projects, such as the former ATV disinfection and microbiological control campaigns, planetary protection-related activities for ExoMars, lunar lander payloads and technology development activities.

General support activities

Laminar flow benches (class 2), CO2 incubators, refrigerators, freezers (from -20 to -170 °C), lab. Centrifuges (18000 g, refrigerated)

Analytical capabilities including fluorescence microscopes (up to x 100), wide-screen imaging, and data/image processing systems

High vacuum pump, Vacuum ovens, furnace

Laboratory tools, like Eppendorf™, automatic pipetting systems

Hardware generic support and verification equipment and tools (oscilloscopes, meters, power supplies…)

SERVICES

This laboratory offers services like

Testing

- Performance evaluation

- Qualification & validation

- Test beds development

- Test methods development

- Life testing

- Environmental testing

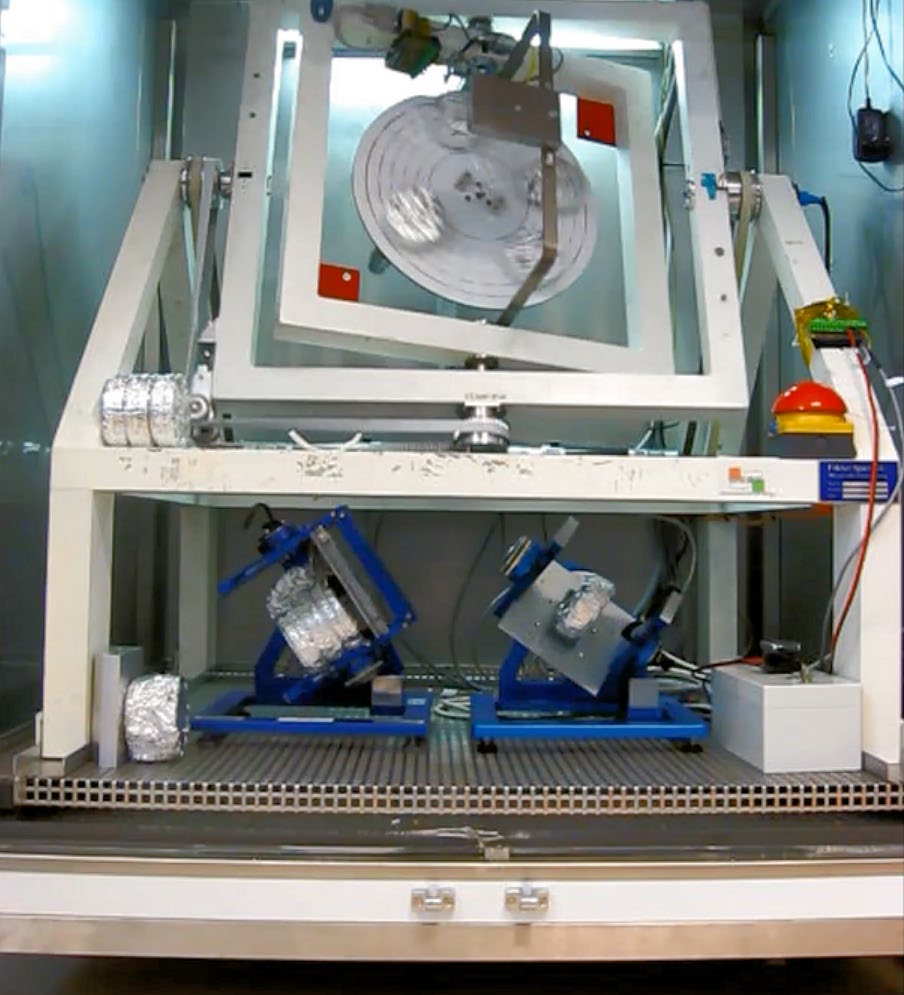

- Hypergravity with the Large Diameter Centrifuge (LDC)

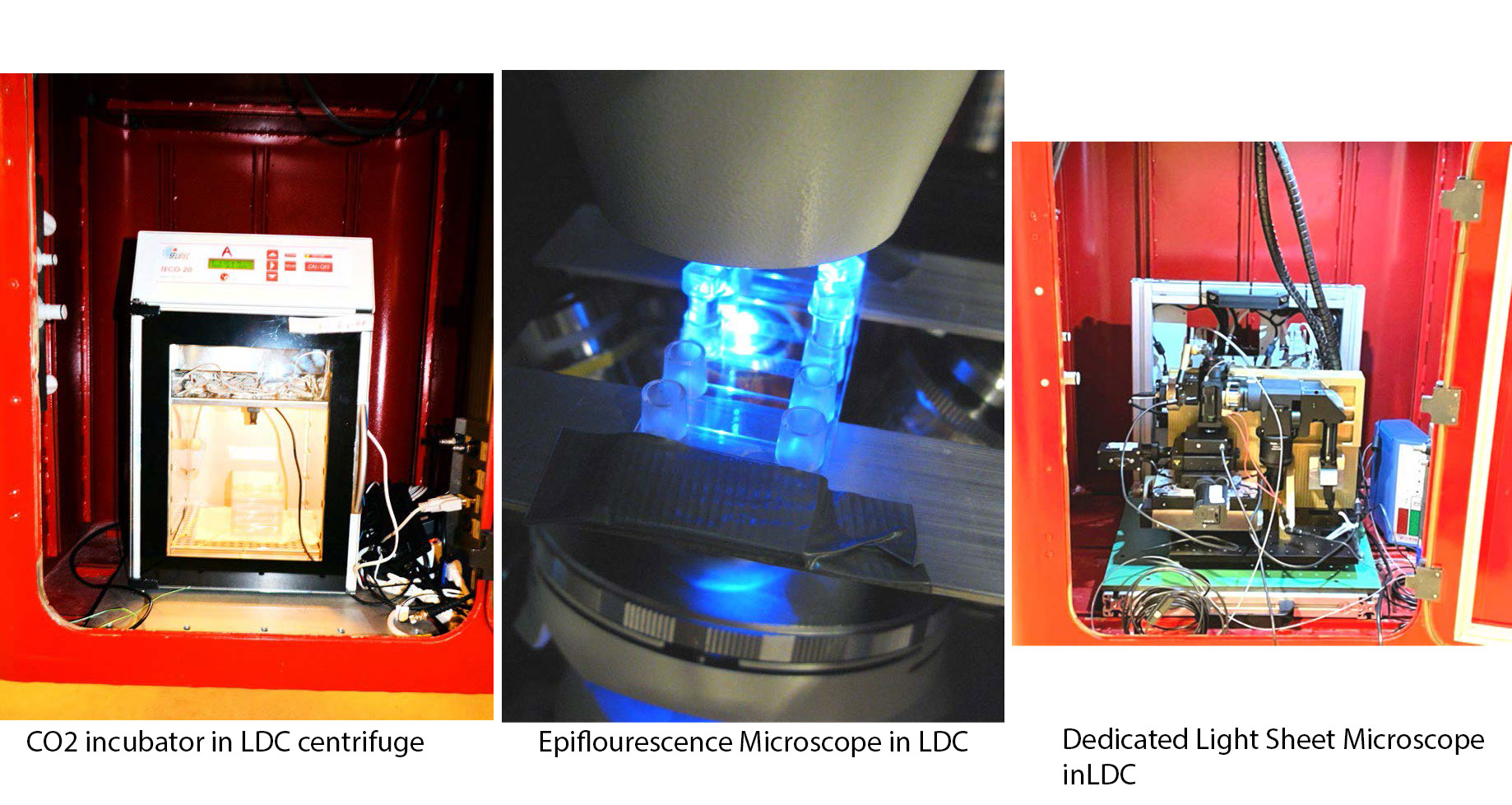

- Hyper-gravity Microscopy

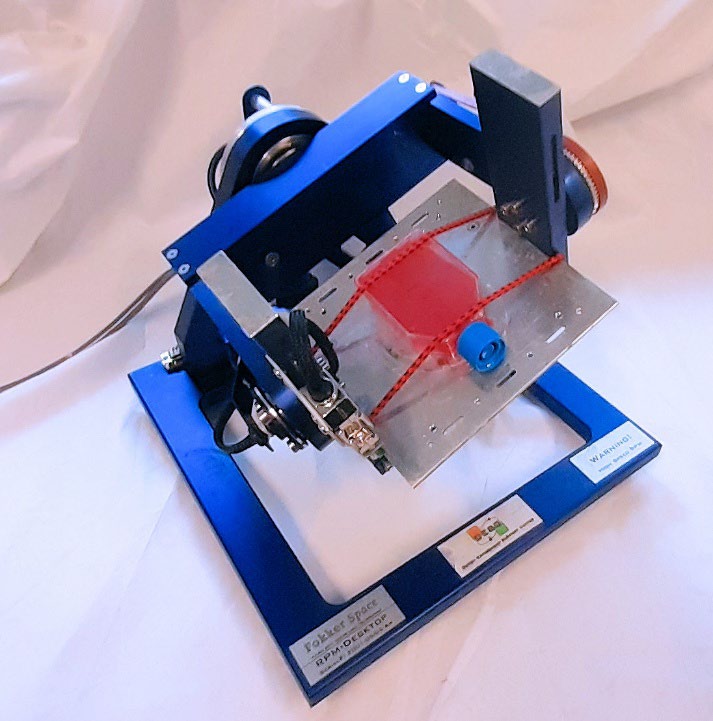

- Microgravity simulation with Random Positioning Machines and Clinostats

- Planetary Protection; Sterilisation/cleanliness

Measurements

- Bio contamination, residual chemical compounds, confirmatory identification of small organic molecules fluorescence Microscopy, 3D light sheet microscopy

Simulation

- Virtual Simulation

- Hyper/microgravity, static g load launch profiles

Analysis

- Liquid chromatography–mass spectrometry, mass spectrometry

Technical expertise

- Consultancy

- Training/courses

Simplified access to the laboratories

- Equipment accessible

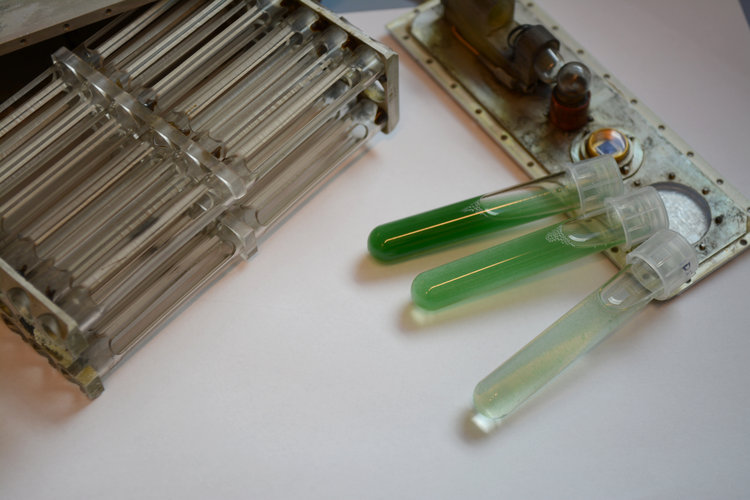

The Lab’s first large-scale use came in 2007, with more than 80 scientists and technicians preparing and testing 35 life and physical science experiments for flight on ESA’s Foton-M3 mission.

The Lab has also contributed to other flight projects, such as developing and validating disinfection procedures for ATV. The Lab supports MELiSSA (Micro-Ecological Life Support System Alternative) activities, developing regenerative life support technologies.

Customers from industry and international instrument teams use the cleanroom facility to do cleaning and sterilisation process qualification and validation for qualification models and flight hardware for the ExoMars 2016 and 2028 missions.

Its Gravity Simulation Lab is used by scientists from all over Europe interested to explore the effect of gravity onto their systems also technology tests and industrial customers that wish to have their set-up exposed to static gravity accelerations with the centrifuge– regularly accessible to student teams through the ESA Education Office’s ‘Spin Your Thesis’ campaigns but also through the Constantly Open Research Announcements (CORA) ground based facilities, or the Open Space Innovation Platform.

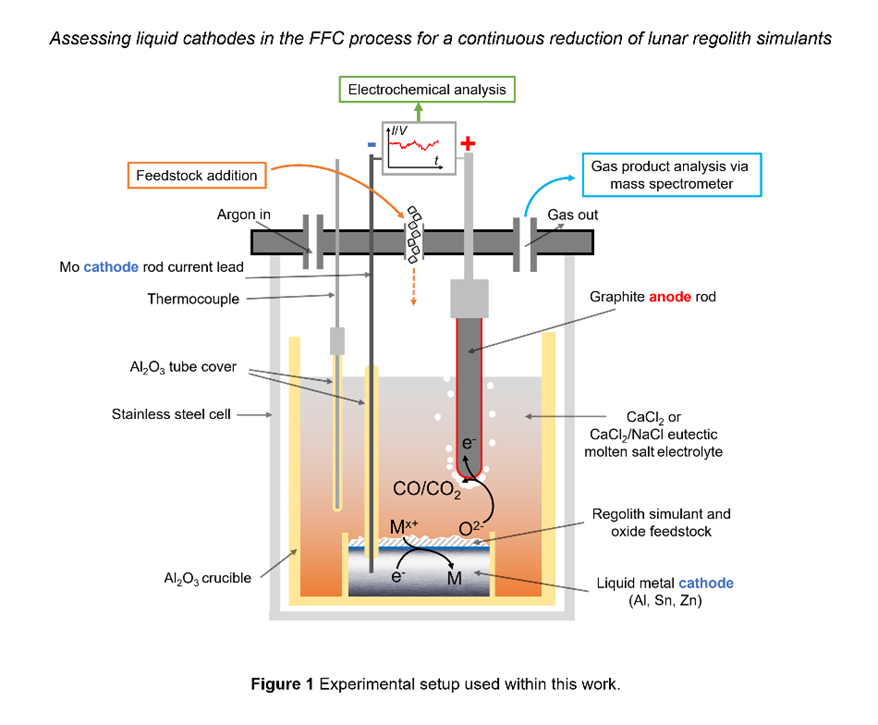

Since 2023, a part of the lab is dedicated as well to research on In Situ resource Utilisation processes, specifically focussing on molten salt electrolysis for the generation of oxygen and metals from minerals.

List of facilities, instruments & Specification

ESA's Life Support & Physical Sciences Instrumentation Laboratory (LIS) is a 720 m² facility, it has 6 main laboratories with state-of-the-art equipment including high-performance analytical instrumentation for chemistry and microbiology, also for cleaning, sterilisation and instruments for gravity related research.

Lab 1

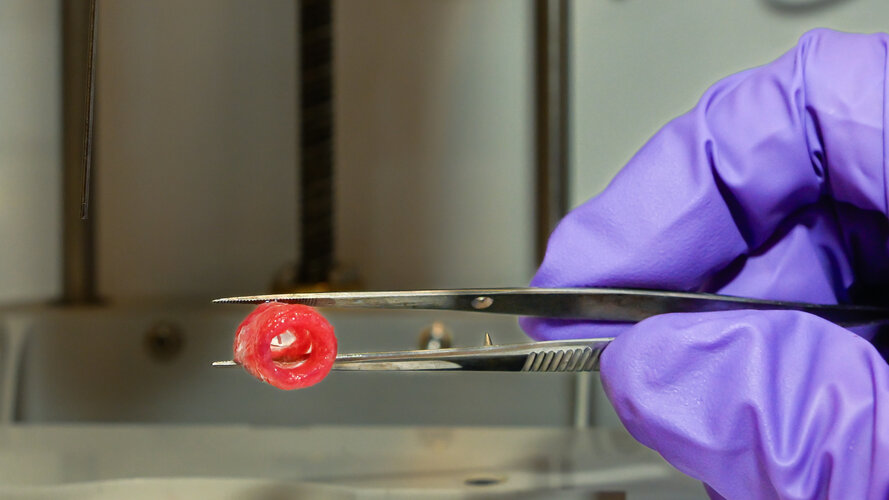

Life Science microbiology lab (100 m²)

Instruments & technical parameters

Large working areas (set up for at least 3 teams) and fully equipped with three ISO5 class 2, laminar flow benches (2 person), three CO2/ O2 incubators, gas supply, fluorescent, inverted and non-inverted microscopes, cell counter, plate reader, micro balances, centrifuges and support equipment etc.

Lab 2

Analytical lab

Instruments & technical parameters

For performing microbiological, chemical analysis and solvent cleaning. The Lab also has vacuum ovens, freeze dryer, furnaces, spectrophotometers, fume ventilation hood and one ISO5 class 2 chemical/laminar flow bench.

Lab 4

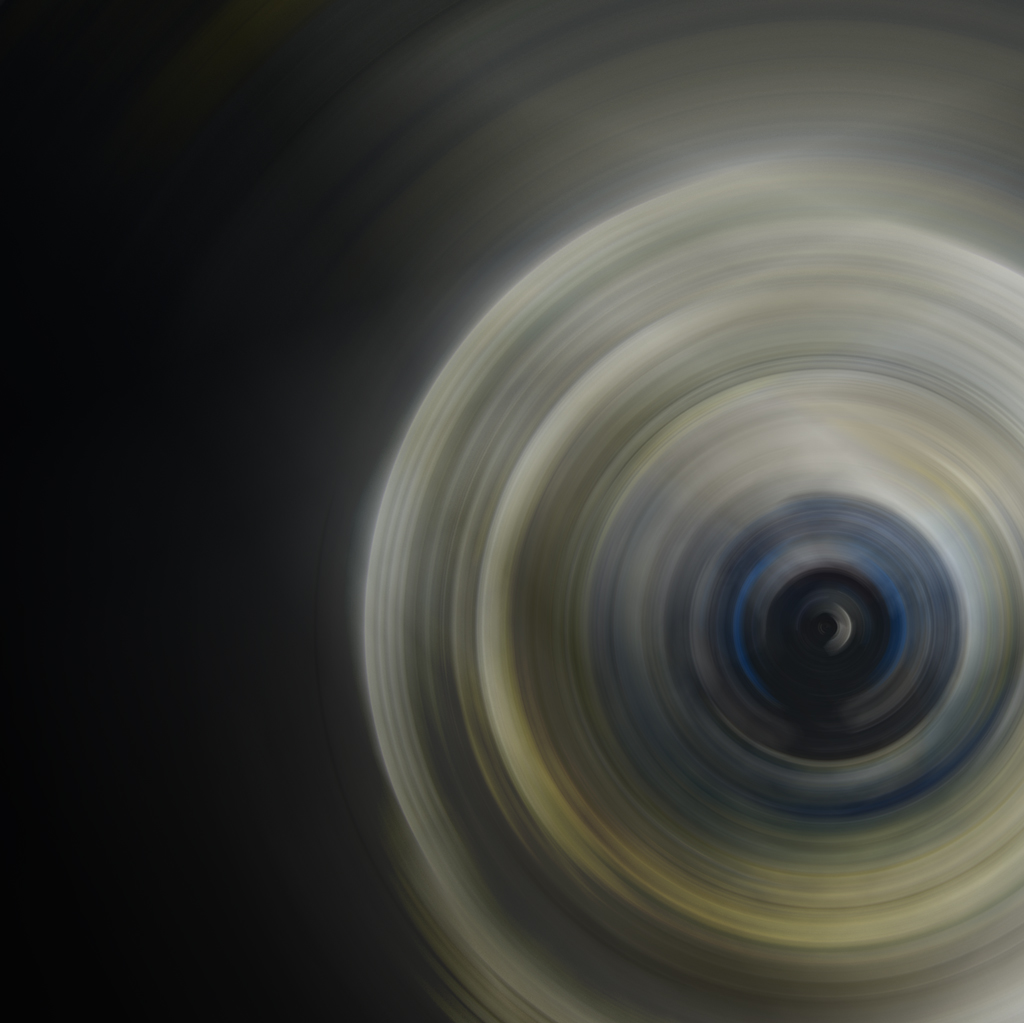

The Gravity Simulation Lab

Instruments & technical parameters

It enables testing in simulated microgravity, simulated partial gravity (e.g. Moon and Mars g) and hypergravity conditions. This facility hosts one large and two small Random Position Machines (RPMs) and clinostats, for microgravity simulation, a MidiCAR centrifuge (100g) and a 8 meter diameter large diameter centrifuge, LDC, equipped with four arms carrying up to six gondolas, accommodating payloads up to 80 kg. The maximum possible acceleration is 20 g for durations up to 6 months. The LDC can host (CO2) incubators for life sciences research, multiwell plate reader, as well as epifluorescence and light sheet microscopes for cell biological studies.

Download Large Diameter Centrifuge (LDC) Manual

Link to LDC publications DOIs in the area of cell biology, plant biology, animal physiology, fluid physics, plasma physics, geology/planetary, technology material sciences and general concepts.

Lab 5

The preparation room

In support of the labs, the facility also includes a Preparation room with a fume hood and balances for chemical preparation, water system (demineralised and ultrapure class 1), autoclaves, -18 and -80 freezers and various areas for chemical storage and glassware.

Lab 6

The In-Situ Resource Utilization Lab (ISRU-Lab)

The In-Situ Resource Utilization Lab (ISRU-Lab) enables research to evaluate possible optimization approaches for the molten salt electrolysis of metal oxides contained within lunar regolith. Locally produced oxygen holds the promise of being used for both life support systems and rocket propellants, being a potential game changer for future lunar settlements.The lab is equipped with high power potentiostats for electrochemical analysis, 2 large and 1 small scale high temperature ovens reaching temperatures beyond 1100 °C and a mass spectrometer for a detailed product gas analysis (O2, CO2, CO, HCl, Cl2, H2O, Ar). The infrastructure enables rapid experimental iteration and deep insights into the underlying electro-deoxidation mechanisms.

ESA External laboratory MELiSSA pilot-plant in UAB Barcelona, Spain

The objective of the MELISSA activity is to define and develop a highly regenerative Life Support System based on microorganism and higher plants, for usage on manned missions beyond low Earth orbit.

The MELISSA ESA external laboratory provides the investigation, engineering and development environment needed for establishing and demonstrating Life Support activities including:

- ECLS feasibility studies

- ECLS design, analysis and verification

- Validation on ground of pre-flight and flight hardware

MELiSSA (Micro-Ecological Life Support System Alternative) is the European Project closed life support system. It aims to produce food, water and oxygen for manned space missions where otherwise these supplies would result in a tremendous cost. Therefore, the life support system has to be increasingly regenerative.

The project targets to ease human exploration of the Solar System, but can also serve current global challenges as waste recycling, water provision, food production in harsh environmental circumstances.

For the MELiSSA Foundation: