ESA Propulsion Laboratory

The ESA Propulsion Laboratory (EPL) is an operational facility at ESTEC in the spacecraft propulsion testing field.

The ESA Propulsion Laboratory (EPL) is an operational facility at ESTEC in the spacecraft propulsion testing field. The EPL provides test services to the ESA Propulsion and Aerothermodynamics Division, which is responsible at European Space Agency for R&D activities and support to projects in the areas of chemical propulsion, electric and advanced propulsion and aerothermodynamics.

For testing requests, access to lab facilities, training and consultancy services, please refer to:

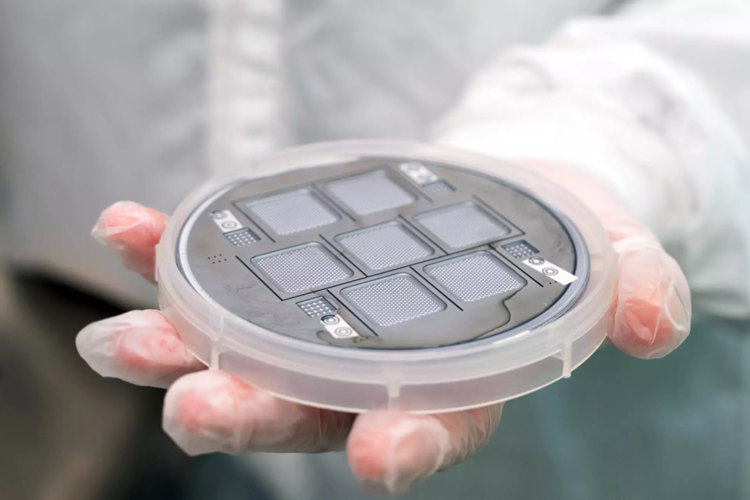

Measurements for electric and cold-gas thrusters and components

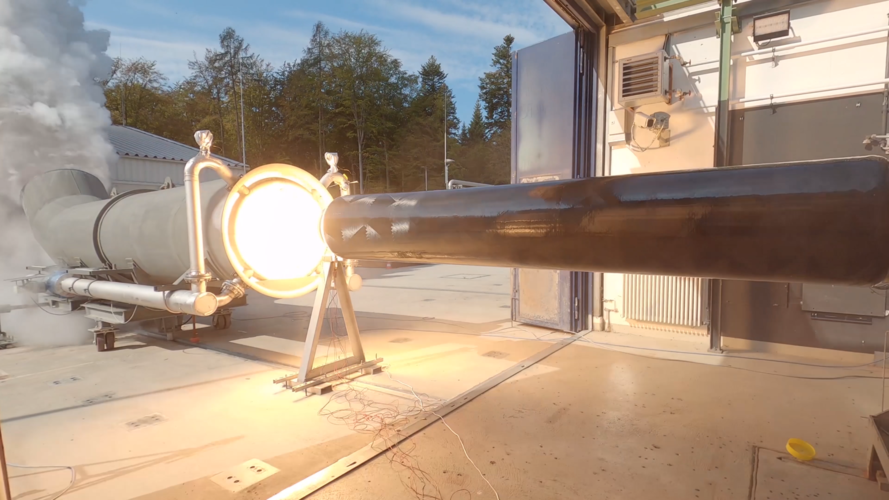

When applicable, the EPL also provides technical advice and support to external organisations for subjects related to propulsion testing and test facilities. Much of the Lab’s work involves characterising engine performance during firing. EPL holds an ISO 9001 certificate and can perform measurements for electric and cold-gas thrusters and components. It exploits in-house procedures, which have demonstrated to be reliable and repeatable for measuring thrust, mass flow and electrical parameters related to propulsion system operations, along with related calibration processes. The laboratory offers also the possibility to perform endurance test campaigns, useful to verify the thrusters performance evolution over time. They can be extended for hundreds or even thousands of hours at a time.

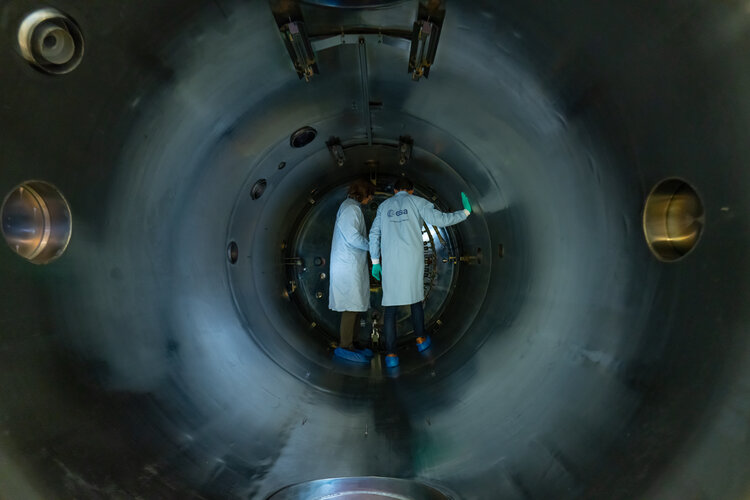

Vacuum chambers Instruments & technical parameters

7 CHAMBERS:

#1 FEEP

#2 Galileo

#3 Gigant

#4 Corona

#5 Electron

#6 MicroNewton

#7 SPF

Main chamber dimensions [m]

Ø0.8 x 1.3

Ø1 x 1.2

Ø1.6 x 2.5

Ø2 x 5

Ø0.8 x 0.5

Ø0.5 x 0.65

Ø2 x 4

Auxiliary chamber dimensions [m]

Ø0.3 x 3

0

Ø0.4 x 0.8

Ø1 x 1.2

0

0

0

PUMPS:

- Scroll

0

0

1x

3x

1x

1x

2x

- Rotary

1x

1x

1x

0

0

0

1x

- Roots Blower

1x

1x

1x

0

0

0

1x

- Turbo

1x

1x

2x

3x

1x

1x

2x

- Cryogenic Pump

3x

1x

2x

1x

0

0

1x

- Cryogenic Head

0

2x

4x

6x

0

0

4x

- Ion Pump

0

0

0

0

0

1x

0

Pumping Speed [L/s]

5,000 (N2)

23,600 (Xe)

53,400 (Xe)

80,000 (Xe)

260 (N2)

500 (N2)

25,000 (Xe)

Beam target

No

No

Yes

Yes

No

No

No

Bake–out system

Yes

Yes

Yes

Yes

No

No

No

EPL Thrust Balances Instruments & technical parameters

Instruments

Range

Uncertainty (best practice)

Resolution

Description

Alta 1–axis optical thrust stand

5-500 mN

±2 mN

Variable

Inversed pendulum with optical strain gauges

Alta Low thrust balance

0.2 - 10 mN

±2 mN

Variable

Inversed pendulum with laser displacement probe

Mettler–Toledo AX504

500 g = 5N

±10 µN

0.1 mg ≡ 1 µN

Modified commercial load–cell

Mettler–Toledo XP2004S

2.3 kg = 23N

±10 µN

0.1 mg ≡ 1 µN

Modified commercial load–cell

NPL micro–thrust balance

1 µN – 1 mN

±0.1 µN

0.1 µN

Null–force folded pendulum (under development)

IRS Impulse Thrust Balance

ìNs - mNs

Modified commercial load–cell

ICL Thrust Balance

1- 600 mN

Flexures dependant

±0.1 mN

Modified commercial load–cell

XPR2004SC

2.3 kg

±0.1 mg

Modified commercial load–cell

Services

Testing

- Performance Evaluation

- Qualification Tests & Validation Tests

- Test Methods Development

- Life Testing

- Anomaly Investigations

- Characterisation

Measurements

- Thrust Measurement

- Efficiency/Specific Impulse Measurement

Simulation

- Modelling

- EcosimPro Simulation Tool Applied to Propulsion System Modelling

Simplified Access to Labs

- Equipment accessible

WE CAN HELP YOU GET THE BEST OUT OF OUR LABORATORIES

FOR FURTHER INFORMATION REGARDING THE ACCESS TO THE LABORATORY

Contact us via email