ESA Space Power Laboratory

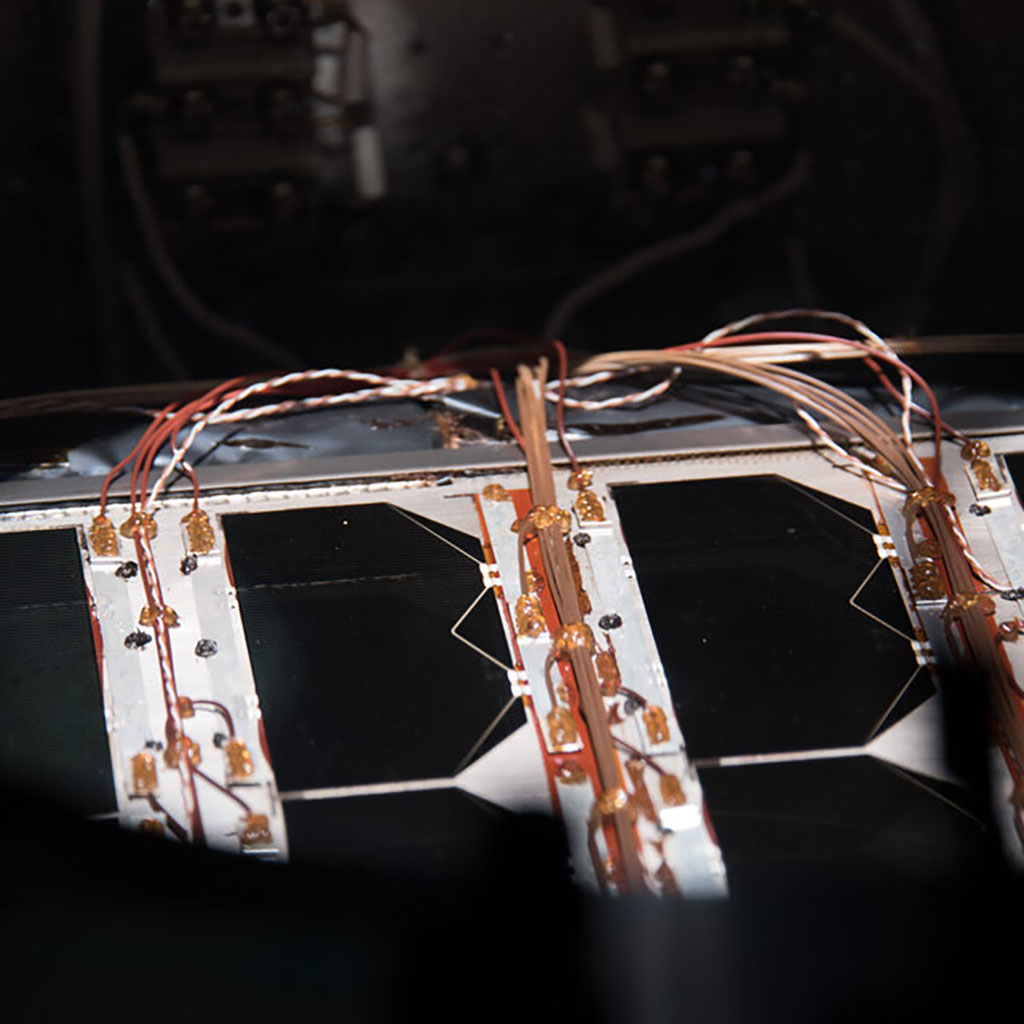

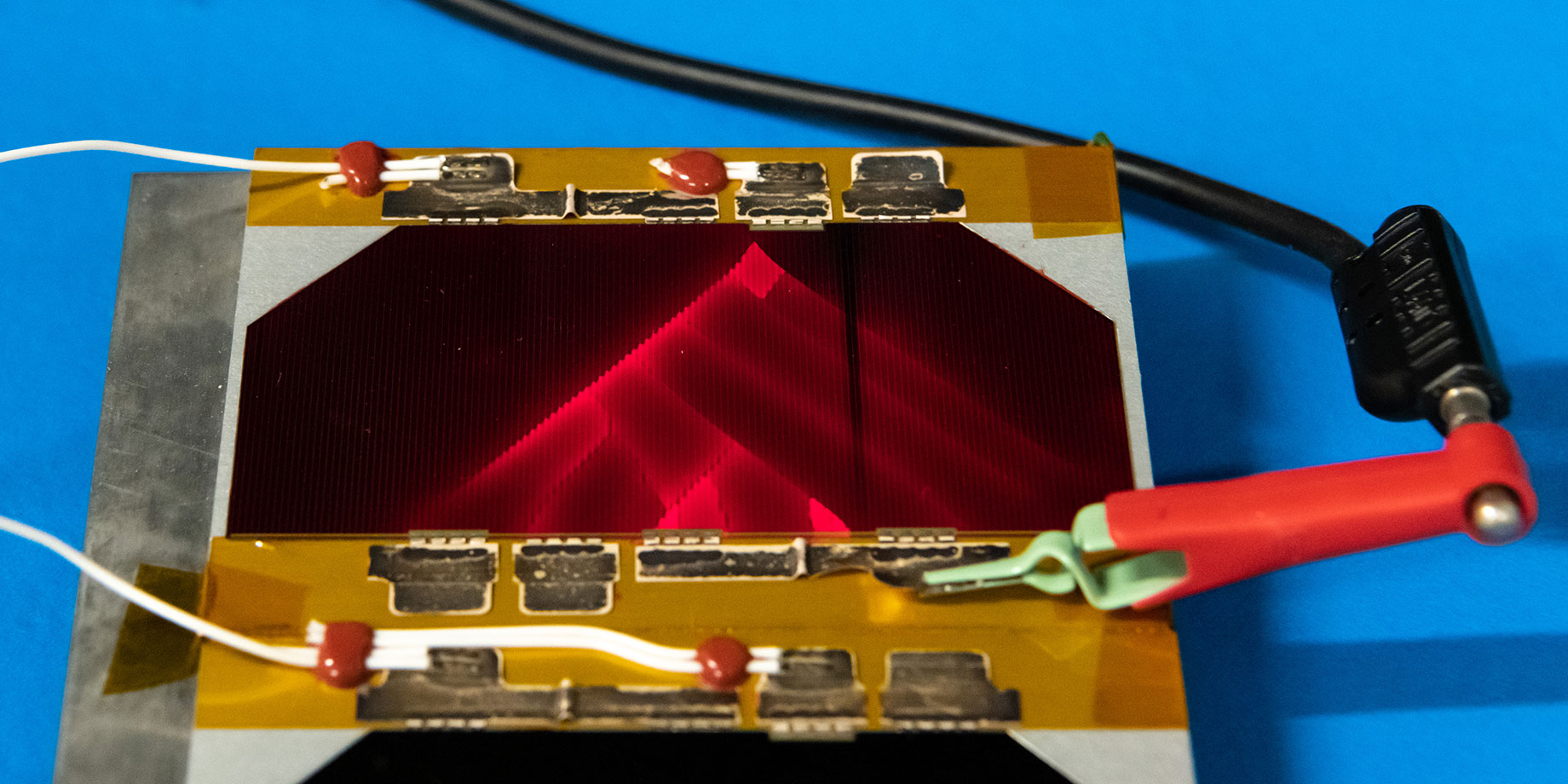

In operation since the 1970s, the ESA Space Power Laboratory is among Europe's leading facilities of this kind. The ESPL performs tests related to all aspects of satellite power systems and equipment, including power conditioning to manage and convert onboard electricity, solar generators based on photovoltaic cells converting sunlight into electrical power as well as space cells and batteries to keep missions operational in all circumstances.

Tests related to all aspects of satellite power systems and equipment

The ESPL provides

an independent and impartial evaluation of power system designs

for ESA programmes, R&D prototypes and Third-Parties activities.

They cover:

The ESPL provides

an independent and impartial evaluation of power system designs

for ESA programmes, R&D prototypes and Third-Parties activities.

They cover:

Characterisation testing of critical power supply components and breadboards

Failure investigation

Environmental testing, e.g. thermal cycling and life test of solar array coupons

Power converter design validation, by e.g. linking them to solar array simulators

High voltage testing in ambient, partial pressure and vacuum conditions

Solar array and cells inspections and performance measurement under simulated sun

Long-term multi-year space battery testing including thousands of charge/discharge cycles

Qualification and acceptance of payloads

Support of launch campaign preparation including health check assessment of batteries

Studying age-based battery phenomena such as self-discharging and memory effects

Software modelling of batteries and solar cells

Support to and preparation of R&D activities and standardisation

Services

Testing

- Performance Evaluation

- Test Methods Development

- Life Testing

- Environmental Testing (For Instance, Thermal Cycling Tests, Thermal Vacuum Test, etc)

- Anomaly Investigations

- Characterisation

- Power Analysis (Power Conversion, Power Distribution, Power Systems)

- Control Loop Test (Bode Plot)

- HV Breakdown Test

- HV Isolation Test

- HV Partial Discharge Test

- HV Corona Test

Measurements

- Prototyping

- Mass Properties Measurement Test

- Electrical Test

Simulation

- Modelling

- Battery Simulator

- Solar Simulator

- Solar Array Simulator

Analysis

- Ageing

- FMECA

- WCA

- PSA

Technical Expertise

- Training

- Development of Space Standards

Learn more about the ESPL Laboratory

For further information regarding the access to the laboratory

Contact us via Email